Ensure that the tape is not covering any areas of the design. Powdered film sheet, conveyor dryer or curing oven, protective hand gloves. Plug the USB drive with the converted design file into the DTG printer.

A design must first be scanned into the system, which is then translated by RIP software program into a set of instructions that the printer can use to print it. I even have had lots of experience in each and I believe there's time and place for each printing technique. If you’d like to have the ability to meet medium-to-large orders for varied materials, then DTF is an efficient pick. DTF printing is a straightforward way to broaden your market share since you can easily print designs for a extensive variety of fabric types that cater to a broad viewers.

Consider it analogous to generating white toner printer transfers. An LED printer prints your image onto a film utilizing white toner printers. After “marrying,” you’ll have a full-color transfer that’s prepared to use. With screen printing, you must use a wide range of ink colours and textures, and you can print on various types of fabric, including 100 percent cotton, polyester, and blends.

Once the printer is finished auto-adjusting the platen, choose the "nozzle check" button. Select the "white" or "shade" buttons inside the nozzle verify setting display screen to perform the check, and hit "print". This number determines the minimal quantity of white ink to be laid down on our movie print. Once this system opens, drag and drop the design file you wish dtg pro to convert within the lower left dialogue field of the display screen .

It’s just a matter of careful positioning if you warmth press it to the substrate. It still requires guide labor to chop and separate all the printed films, but you’ll spend much much less time preparing your shirts than DTG printing. The omission of the pretreatment process more or less provides DTF printing a significant time benefit over DTG printing. With the best equipment setup in your shop, a staff of two can end a print run, from pretreatment to ultimate heat press, in an hour with six to seven shirts ready. Further workspace optimization can easily let you match the 15 to 20 shirts per hour statistic.

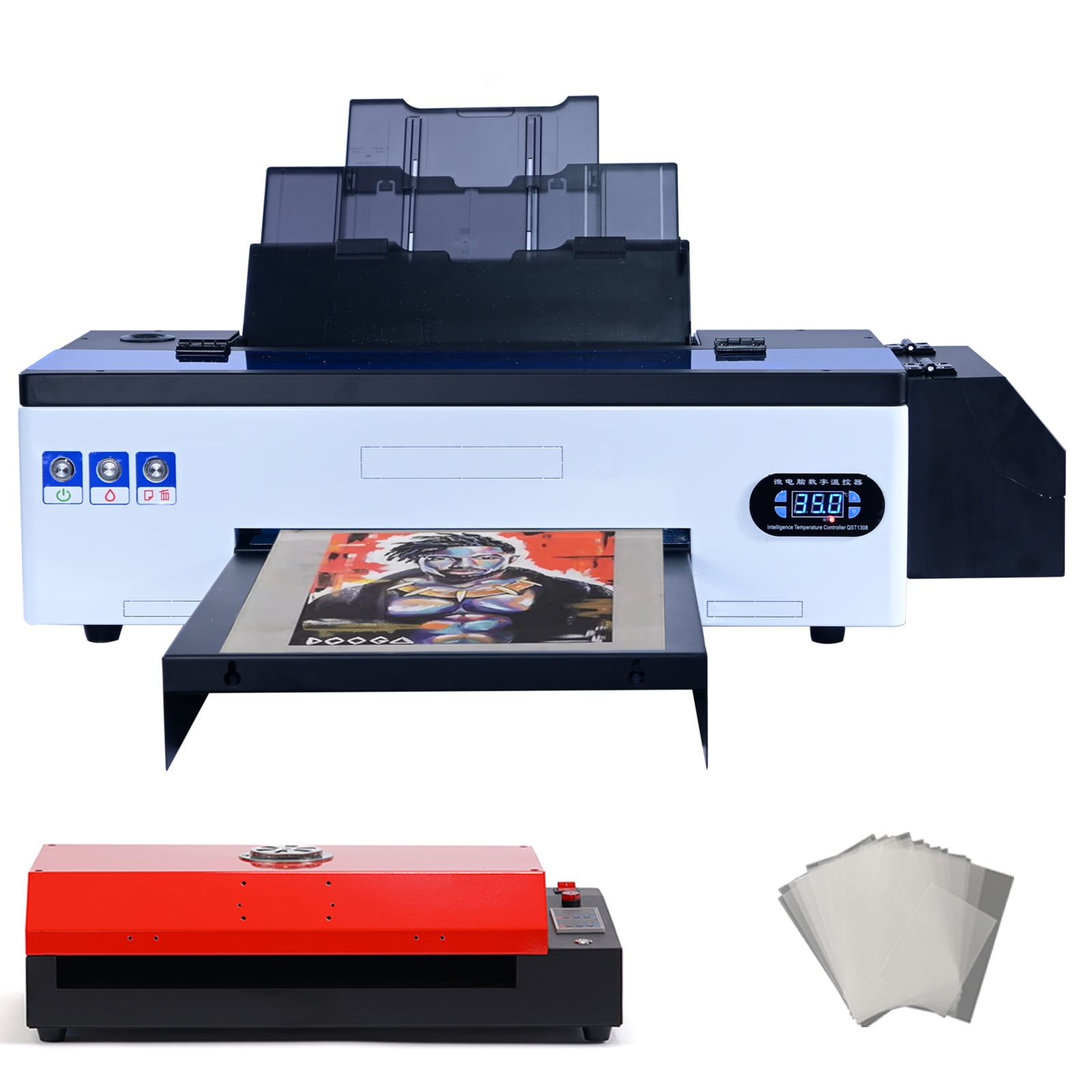

Moreover, DTF printing is economical and environmentally friendly since it requires much less ink than DTG. Maintenance is certainly one of the most necessary concerns when you’re thinking about a printer to purchase. Both DTG and DTF printers have comparatively related upkeep cycles. However, DTF printers benefit from utilizing much less white ink than DTG printing; white ink is the source of many maintenance points where printers are concerned. For such a transformed printer, costs go from as little as $600 to $2,000 from numerous on-line sellers.

Making transfers is presently not an option for house owners of direct-to-garment printers. As a result, DTG printer homeowners are unable to take part in the complete transfer trade. Synthetics in dark hues look wonderful, and so they look excellent in bright colours as well. Cotton shirts look great in every hue – even inexpensive cotton shirts! So, if you’re printing 500 shirts and solely have one heat-press, every shirt software ought to take roughly 30 seconds. There isn't any must pre-treat the fabric with DTF printing as a outcome of the design is pre-printed on a film that should be transferred.

Mark can be a co-host of the Custom Apparel Startups Podcast. If you have a home-based business or smaller store that sells customized Ts in the dozens, or even hundreds, you must seriously think about a direct-to-garment printer. DigitalHeat FX DTF-24H2 is a superb machine, it is giant whenever you embody the dryer, and loud because of the automatic shaker to use the new melt powder to the transfers. Dark-colored synthetics are nice; completely on gentle colors too.